Product Information

- TOP

- English Top

- ToYo TooL

- Rotary Tools

- Twist Chamfer Mill

- Twist Chamfer Mill

Twist Chamfer Mill

Product lineup

Solid Carbide 90° Front Chamfering End Mill

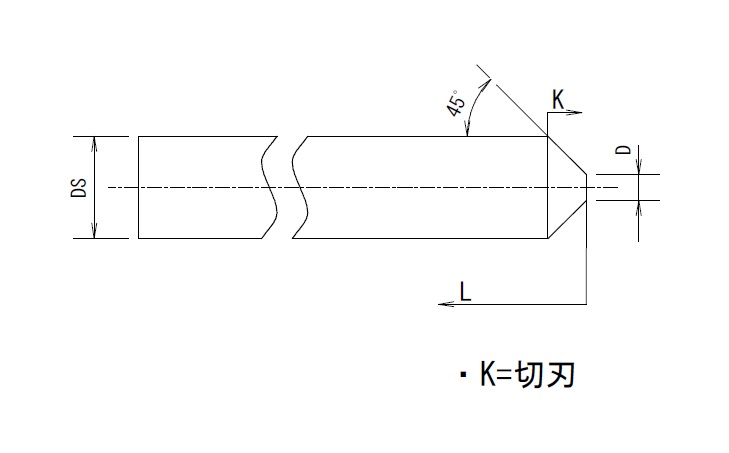

| Model No. Non-coating type | Model No. Coating type | Tip diameter D | Effective blade length K | Number of flutes | Shank diameter DS | Full length L |

|---|---|---|---|---|---|---|

| TCM90-3 | TCM90C-3 | 0.5 | 1.25 | 3 | 3 | 40 |

| TCM90-4 | TCM90C-4 | 0.5 | 1.75 | 3 | 4 | 50 |

| TCM90-6 | TCM90C-6 | 0.75 | 2.625 | 5 | 6 | 60 |

| TCM90-8 | TCM90C-8 | 1.25 | 3.375 | 5 | 8 | 60 |

| TCM90-10 | TCM90C-10 | 2.5 | 3.75 | 7 | 10 | 70 |

| TCM90-12 | TCM90C-12 | 2.5 | 4.75 | 7 | 12 | 70 |

| TCM90-10-11S | TCM90C-10-11S | 4 | 3 | 11 | 10 | 70 |

| TCM90-12-11S | TCM90C-12-11S | 4 | 4 | 11 | 12 | 70 |

Recommended cutting conditions

| Work material | Aluminum alloy | General steel | Stainless steel | Titanium alloy | Heat resistant alloy |

|---|---|---|---|---|---|

| Cutting speed (m/min) | 85~175 | 40~90 | 30~60 | 25~55 | 20~45 |

| Shank diameter / DS | Feed per tooth (mm/tooth) | Feed per tooth (mm/tooth) | Feed per tooth (mm/tooth) | Feed per tooth (mm/tooth) | Feed per tooth (mm/tooth) |

| φ3. / φ4. | 0.01~0.05 | 0.025~0.065 | 0.02~0.06 | 0.025~0.05 | 0.02~0.04 |

| φ6. / φ8. | 0.015~0.055 | 0.02~0.06 | 0.015~0.055 | 0.02~0.055 | 0.01~0.05 |

| φ10. / φ12. | 0.015~0.055 | 0.015~0.055 | 0.01~0.05 | 0.02~0.045 | 0.01~0.035 |

| Cutting speed (m/min) | 150~305 | 100~225 | 90~180 | 75~165 | 65~150 |

| φ10. / φ12.(11S) | ~0.03 | ~0.035 | ~0.03 | ~0.025 | ~0.035 |

| Chamfer width at one time | ~0.3DS | ~0.15DS | ~0.2DS | ~0.15DS | ~0.15DS |

*Since the recommended cutting conditions are calculated by us, fine adjustment is required on the material, work condition, processing machine, etc.

*Recommended cut direction : Down cut

*It is recommended to use "oil-based coolant / water-soluble coolant" during processing.

*Depending on the material, work condition, processing machine, etc., cut in several times.

*In order to suppress the occurrence of "tool damage / chatter / burr etc.,"pay attention to "clamp / tool runout of machining work".

*If you want to increase the surface roughness, set a low feed amount per blade or a small cut chamfer amount.

*When chamfering holes by thrusting, set the cutting speed low.

*If the amount of protrusion is long, set the condition low.

Recommended type

| Aluminum alloy | General steel | Stainless steel | Titanium alloy | Heat resistant alloy | |

|---|---|---|---|---|---|

| Non-coating type | ◎ | △ | △ | ○ | × |

| Coating type | ○ | ○ | ◎ | ◎ | ○ |

Product video

Actual footage of machining with this tool. 0:23~

Catalog

List of products

Rotary Tools

Back surface dedicated tool

Twist Chamfer Mill

Carbide Chamfering Cutter Series

- Carbide Chamfering Cutter BCM/WCM for Aluminum

- Carbide Chamfering Cutter SUS-BCM/WCM for Stainless Steel

- Carbide Chamfering Cutter STEEL-BCM/WCM for Standard Steel

- Carbide Chamfering Cutter TITAN-BCM/WCM for Titanium

Carbide Round Chamfering Cutter Series

Carbide Chamfering Drill Series

Carbide Special-use Rotary Tools

Lathe Tools

PCD Brazing Bite

- RGT-NN Series for Outer Diameter“Front-milling Undercutter”

- RGT-KH Series“Single-edged Blade” for Outer Diameter

- RGT-KK Series“Acute-angle Blade” for Outer Diameter

- RGT-UH Series“Back-milling Cutter” for Outer Diameter

- RGT-MI Series“Grooving Cutter” for Outer Diameter

- RGT-TK Series“Protrusion Cutter” for Outer Diameter

- RGT-VM Series“90° V Grooving, Chamfering Cutter” for Outer Diameter

- RGT-NK Series“60° Threading Cutter” for Outer Diameter

- RTT-NN Series“Front-milling Undercutter” for Outer Diameter

- RTT-K60 SeriesGeneral purpose “60° Straight-turning Tool”

- RTT-CK90 SeriesGeneral purpose “90° Angle Blade”

- RTT-CK60 SeriesGeneral purpose “60° Angle Blade”

- RTT-CK30 SeriesGeneral purpose “30° Angle Blade”

- RNT-NN Series“Front-milling Undercutter” for Inner Diameter

- RNT-KH Series“Single-edged Blade” for Inner Diameter

- RNT-KK Series“Acute-angle Blade” for Inner Diameter

- RNT-NU Series“Extra Undercutter” for Inner Diameter

- RNT-UH Series“Rear-milling Cutter” for Inner Diameter

- RNT-MI Series“Grooving Cutter” for Inner Diameter

- RNT-TMR Series“End-grooving Cutter,” Right-handed

- RNT-TML Series“End-grooving Cutter,” Left-handed

- RNT-NK Series“60° Threading Cutter” for Inner Diameter

- RNT-90VM Series“90° V Grooving, Chamfering Cutter” for Inner Diameter

- RSNT-NN Series“Front-milling Undercutter” for Small Inner Diameter

- RSNT-KH Series“Single-edged Blade” for Small Inner Diameter

- RSNT-KK Series“Acute angle Blade” for Small Inner Diameter

- RSNT-UH Series“Rear-milling Cutter” for Small Inner Diameter

- RSNT-MI Series“Grooving Cutter” for Small Inner Diameter

- RSNT-NK Series“60° Threading Cutter” for Small Inner Diameter

- RSNT-90VM Series“90° V Grooving, Chamfering Cutter” for Small Inner Diameter

PCD Insert Tip Holder

- Undercutter Holder for Outer Diameter(Gang Tool Type)

- Acute-angle Blade Holder for Outer Diameter(Gang Tool Type)

- Single-edged Blade Holder for Outer Diameter(Gang Tool Type)

- GT Holder for Outer DiameterBack-milling/Deep Grooving

- Shallow Grooving Cutter Holder for Outer Diameter (Gang Tool Type)

- Undercutter Holder for Inner Diameter(Gang Tool Type)

- V-shaped Acute-angle Blade Holder for Inner Diameter(Gang Tool Type)

- D-shaped Acute-angle Blade Holder for Inner Diameter(Gang Tool Type)

- Single-edged Blade Holder for Inner Diameter(Gang Tool Type)

- NT Holder for Inner DiameterBack-milling/Deep Grooving

- Shallow Grooving Cutter Holder for Inner Diameter(Gang Tool Type)

- Undercutter Holder for Outer Diameter(Turret Type)

- Single-edged Blade Holder for Outer Diameter(Turret Type)

- 80° Angle Blade Holder for Outer Diameter(Turret Type)

- Shallow Grooving Cutter Holder for Outer Diameter(Turret Type)