Product Information

- TOP

- English Top

- ToYo TooL

- Rotary Tools

- Carbide Chamfering Drill Series

- Carbide Chamfering Drill DCA with 90° Unequal Lead for Aluminum (for Tap Lower Hole)

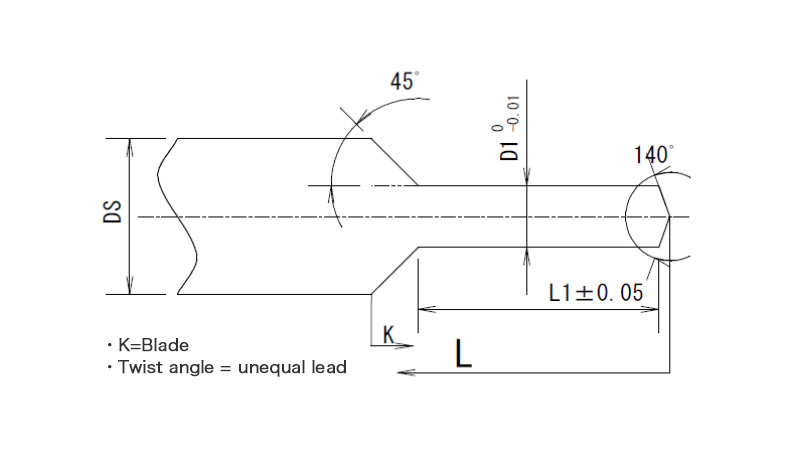

Carbide Chamfering Drill DCA with 90° Unequal Lead for Aluminum (for Tap Lower Hole)

Product lineup

| Item no. | Model no. | Drill diameter/D1 | Blade length/L1 | Shank diameter/DS | Total length/L | Tip angle | Twist angle (unequal lead) | No. of tips | Target tap size |

|---|---|---|---|---|---|---|---|---|---|

| 1 | DCA1.1-3.2-DS3 | 1.1 | 3.2 | Φ3 | 50 | 140° | 5-35° | 2 | M1.4×0.3 |

| 2 | DCA1.1-5.2-DS3 | 1.1 | 5.2 | Φ3 | 50 | 140° | 5-35° | 2 | M1.4×0.3 |

| 3 | DCA1.25-3.2-DS3 | 1.25 | 3.2 | Φ3 | 50 | 140° | 5-35° | 2 | M1.6×0.35 |

| 4 | DCA1.25-6.2-DS3 | 1.25 | 6.2 | Φ3 | 50 | 140° | 5-35° | 2 | M1.6×0.35 |

| 5 | DCA1.35-3.2-DS3 | 1.35 | 3.2 | Φ3 | 50 | 140° | 5-35° | 2 | M1.7×0.35 |

| 6 | DCA1.35-6.2-DS3 | 1.35 | 6.2 | Φ3 | 50 | 140° | 5-35° | 2 | M1.7×0.35 |

| 7 | DCA1.6-3.2-DS4 | 1.6 | 3.2 | Φ4 | 50 | 140° | 5-35° | 2 | M2.×0.4 |

| 8 | DCA1.6-6.2-DS4 | 1.6 | 6.2 | Φ4 | 50 | 140° | 5-35° | 2 | M2.×0.4 |

Recommended cutting conditions

| Cutting speed (m/min) | 30-80m/min |

| Feed rate per rotation (mm/rev) | 0.02-0.06mm/rev |

* The values for recommended cutting conditions are calculated by Toyo, and may need to be slightly modified to match the material, condition of the workpiece, the processing machine and so on.

* Step processing at around 0.25D–0.5D may be required depending on the material, workpiece, processing machine and so on.

List of products

Rotary Tools

Back surface dedicated tool

Twist Chamfer Mill

Carbide Chamfering Cutter Series

- Carbide Chamfering Cutter BCM/WCM for Aluminum

- Carbide Chamfering Cutter SUS-BCM/WCM for Stainless Steel

- Carbide Chamfering Cutter STEEL-BCM/WCM for Standard Steel

- Carbide Chamfering Cutter TITAN-BCM/WCM for Titanium

Carbide Round Chamfering Cutter Series

Carbide Chamfering Drill Series

Carbide Special-use Rotary Tools

Lathe Tools

PCD Brazing Bite

- RGT-NN Series for Outer Diameter“Front-milling Undercutter”

- RGT-KH Series“Single-edged Blade” for Outer Diameter

- RGT-KK Series“Acute-angle Blade” for Outer Diameter

- RGT-UH Series“Back-milling Cutter” for Outer Diameter

- RGT-MI Series“Grooving Cutter” for Outer Diameter

- RGT-TK Series“Protrusion Cutter” for Outer Diameter

- RGT-VM Series“90° V Grooving, Chamfering Cutter” for Outer Diameter

- RGT-NK Series“60° Threading Cutter” for Outer Diameter

- RTT-NN Series“Front-milling Undercutter” for Outer Diameter

- RTT-K60 SeriesGeneral purpose “60° Straight-turning Tool”

- RTT-CK90 SeriesGeneral purpose “90° Angle Blade”

- RTT-CK60 SeriesGeneral purpose “60° Angle Blade”

- RTT-CK30 SeriesGeneral purpose “30° Angle Blade”

- RNT-NN Series“Front-milling Undercutter” for Inner Diameter

- RNT-KH Series“Single-edged Blade” for Inner Diameter

- RNT-KK Series“Acute-angle Blade” for Inner Diameter

- RNT-NU Series“Extra Undercutter” for Inner Diameter

- RNT-UH Series“Rear-milling Cutter” for Inner Diameter

- RNT-MI Series“Grooving Cutter” for Inner Diameter

- RNT-TMR Series“End-grooving Cutter,” Right-handed

- RNT-TML Series“End-grooving Cutter,” Left-handed

- RNT-NK Series“60° Threading Cutter” for Inner Diameter

- RNT-90VM Series“90° V Grooving, Chamfering Cutter” for Inner Diameter

- RSNT-NN Series“Front-milling Undercutter” for Small Inner Diameter

- RSNT-KH Series“Single-edged Blade” for Small Inner Diameter

- RSNT-KK Series“Acute angle Blade” for Small Inner Diameter

- RSNT-UH Series“Rear-milling Cutter” for Small Inner Diameter

- RSNT-MI Series“Grooving Cutter” for Small Inner Diameter

- RSNT-NK Series“60° Threading Cutter” for Small Inner Diameter

- RSNT-90VM Series“90° V Grooving, Chamfering Cutter” for Small Inner Diameter

PCD Insert Tip Holder

- Undercutter Holder for Outer Diameter(Gang Tool Type)

- Acute-angle Blade Holder for Outer Diameter(Gang Tool Type)

- Single-edged Blade Holder for Outer Diameter(Gang Tool Type)

- GT Holder for Outer DiameterBack-milling/Deep Grooving

- Shallow Grooving Cutter Holder for Outer Diameter (Gang Tool Type)

- Undercutter Holder for Inner Diameter(Gang Tool Type)

- V-shaped Acute-angle Blade Holder for Inner Diameter(Gang Tool Type)

- D-shaped Acute-angle Blade Holder for Inner Diameter(Gang Tool Type)

- Single-edged Blade Holder for Inner Diameter(Gang Tool Type)

- NT Holder for Inner DiameterBack-milling/Deep Grooving

- Shallow Grooving Cutter Holder for Inner Diameter(Gang Tool Type)

- Undercutter Holder for Outer Diameter(Turret Type)

- Single-edged Blade Holder for Outer Diameter(Turret Type)

- 80° Angle Blade Holder for Outer Diameter(Turret Type)

- Shallow Grooving Cutter Holder for Outer Diameter(Turret Type)